We are much more than a supplier; we are a strategic partner. We create unique and innovative packaging that is highly artistic and supremely functional. We offer a complete range of services: from design and R&D, to the processing of digital data in pre-press, from printing with the latest generation systems to operations, fulfilment and logistics. At Pozzoli the entire production process is managed internally to transform our customers’ wishes into reality.

Our production process

We give shape, colour and substance to our customers’ emotions

We manage the entire production process

1

2

3

4

5

6

7

8

Our customizations:

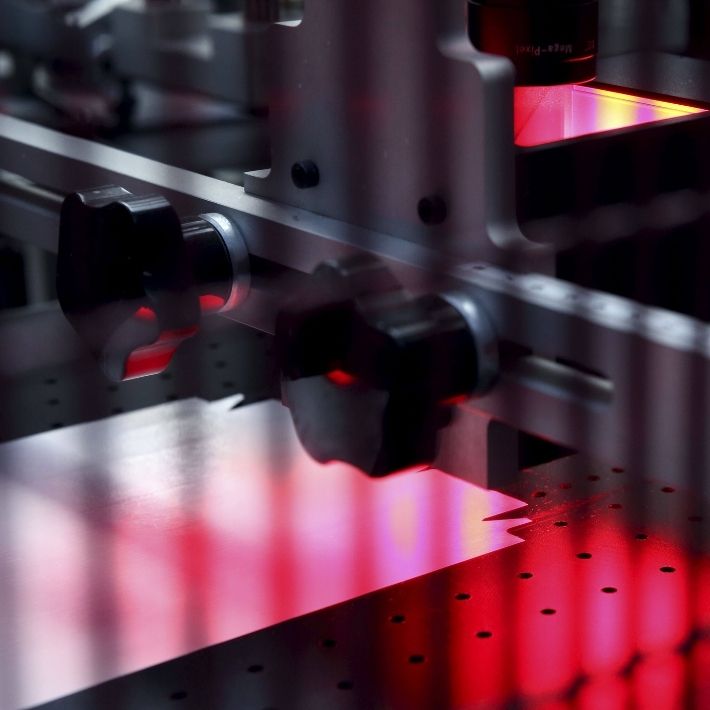

UV printing on special paper and covering materials

UV printing on plastic and laminated materials

Printing with biodegradable inks and food contact inks

Lamination

Hot foil printing and micro-engravings

Silkscreen varnish

Flocking

Embossing and texture

Reliefs

Special die cutting (including laser)