Vinyl inner sleeves, spined sleeve and gatefolds serve different roles in the packaging and presentation of records. Vinyl inner sleeves are usually made from plain paper, poly-lined paper, or anti-static materials and protect the surface of the record from dust, scratches, and static buildup. These sleeves are essential for preserving playback quality and preventing wear during handling and storage. It’s also possible to have printed inner sleeve.

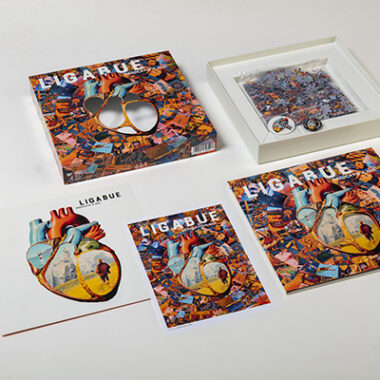

A spined sleeve is usually made of cardboard or recycled board, that encloses both the record and its inner sleeve. Beyond protecting the vinyl from dust, light, and damage, it plays a central role in the visual identity of a release. Jackets can vary in material thickness and finish—ranging from standard uncoated cardboard to glossy or matte laminated stock, and even special textures like kraft paper or soft-touch finishes. They are often printed in full color with high-resolution artwork, track listings, liner notes, and other branding elements using offset or digital printing techniques. Some editions may include specialty inks, embossing, foil stamping, or spot UV to enhance design impact and collectability.

Gatefolds, on the other hand, are a type of outer jacket that could open like a book, offering one or more internal pockets to house records. Commonly used for double LPs, gatefolds are also a popular choice for single LPs when a premium presentation is desired. They provide ample space for expanded artwork, liner notes, lyrics, or band photography, making them especially appealing to collectors and fans.

From a manufacturing perspective, gatefolds allow for greater creative freedom and visual impact, especially when enhanced with finishes like matte or gloss lamination, spot UV, foil stamping, or embossing. High-quality cardstock and custom printing options can further elevate the product, turning the packaging itself into a collectible object.